PALE HORSE CONCEALMENT SOLUTIONS

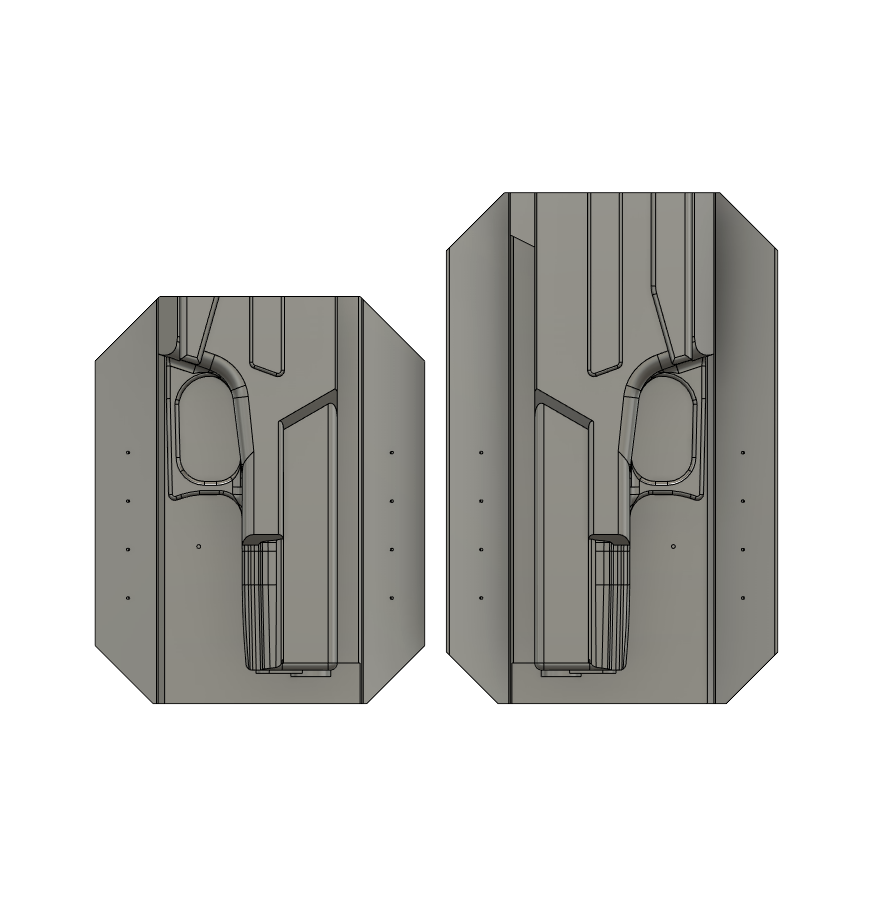

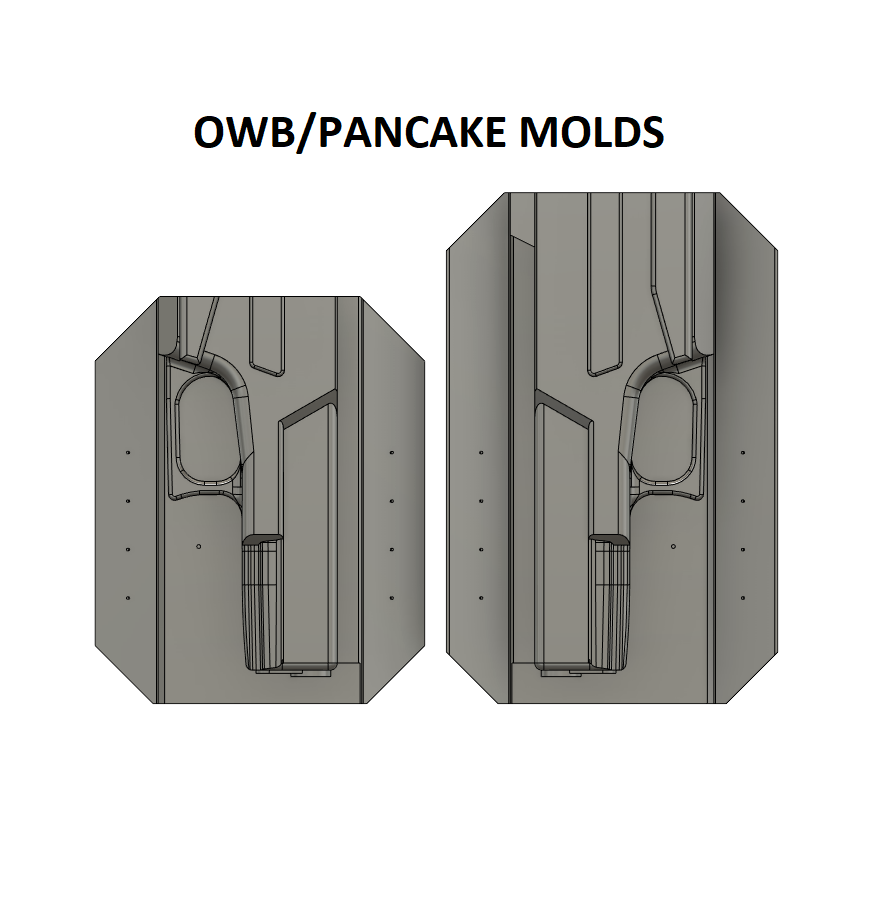

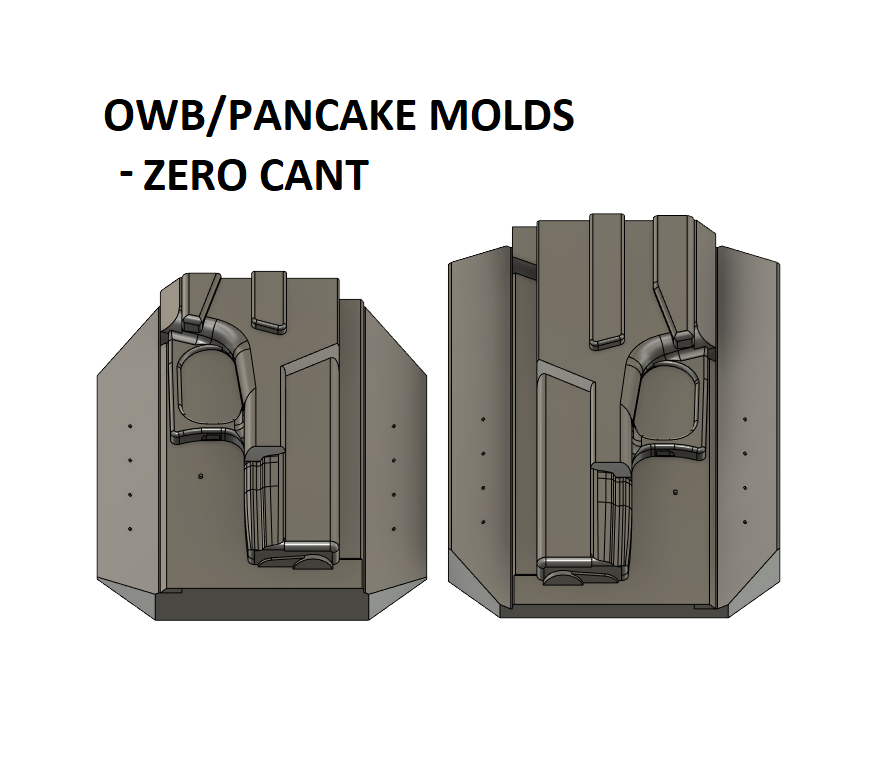

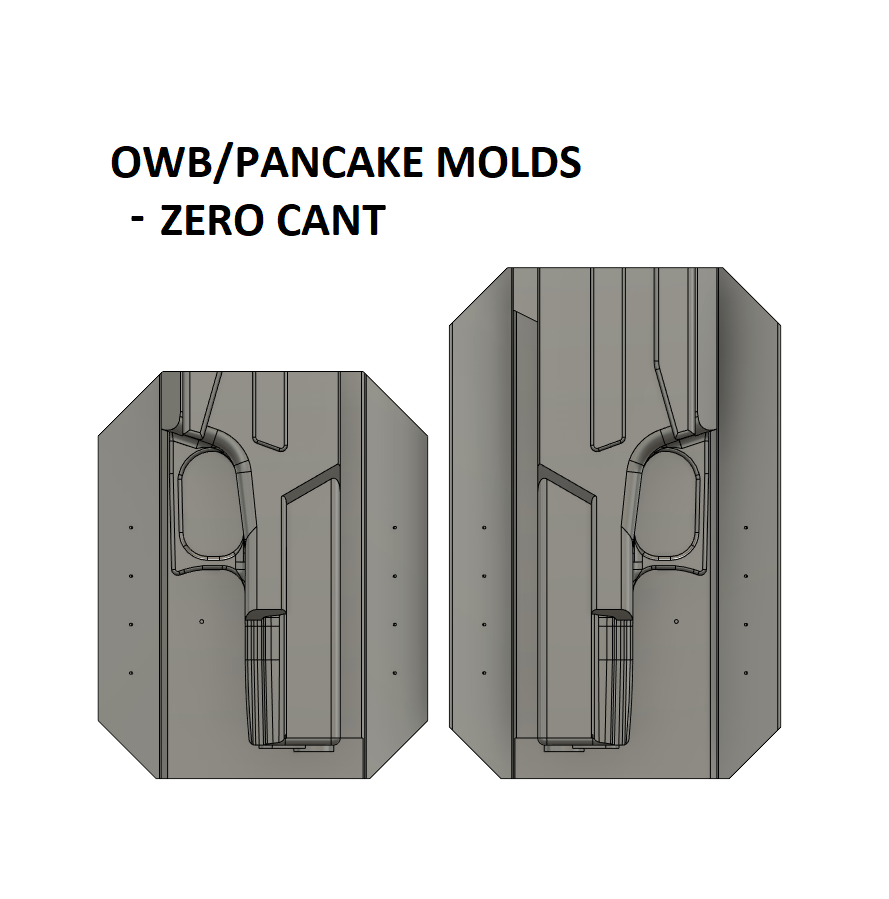

OWB/PANCAKE MOLDS

OWB/PANCAKE MOLDS

Couldn't load pickup availability

LEAD TIME IS BETEEN 2 TO 3 WEEKS ON AVERAGE

ALL MOLDS ARE MADE TO ORDER. WE DO NOT GENERALLY KEEP STOCK ON HAND.

PICTURES SHOWN MAY NOT REPRESENT THE MODEL YOU'RE LOOKING FOR. THEY ARE ONLY INTENDED TO ILLUSTRATE THE MOLD STYLES THAT ARE AVAILABLE.

-MOLD FEATURES

BLOCKED OUT CONTROLS (EJECTION PORT, SIGHT CHANNEL, MAGAZINE RELEASE, SLIDE LOCK LEVERS, SAFETIES, AND TRIGGER GUARD)

ADJUSTABLE RETENTION BUILT IN – MEANT FOR 0.25” RUBBER WASHERS

15 DEGREE DRAFT CUT FOR EASIER MOLD REMOVAL

WINGS ARE SLANTED AT A 30 DEGREE ANGLE TO HELP CONFORM THE HOLSTER TO THE CURVES OF THE HUMAN BODY.

MOLDS ARE MADE FOR ONLY ONE HAND ORIENTATION. THERE IS AN OUTER HALF AND AN INNER HALF OF THIS MOLD. THE END PRODUCT MUST BE FASTENED TOGETHER.

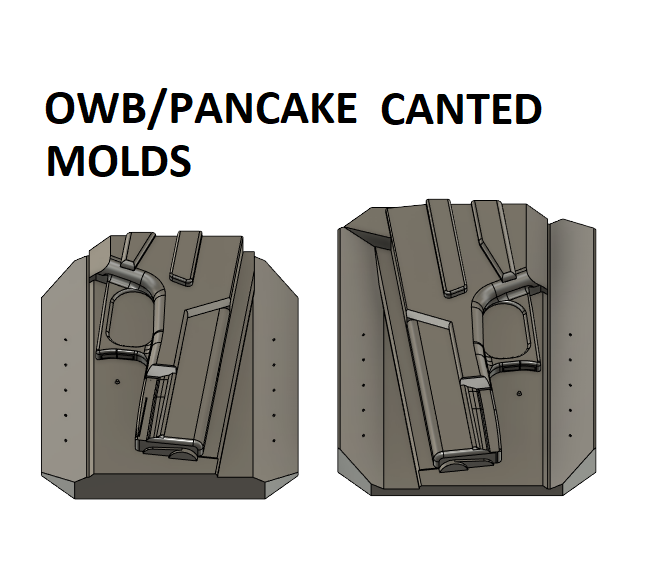

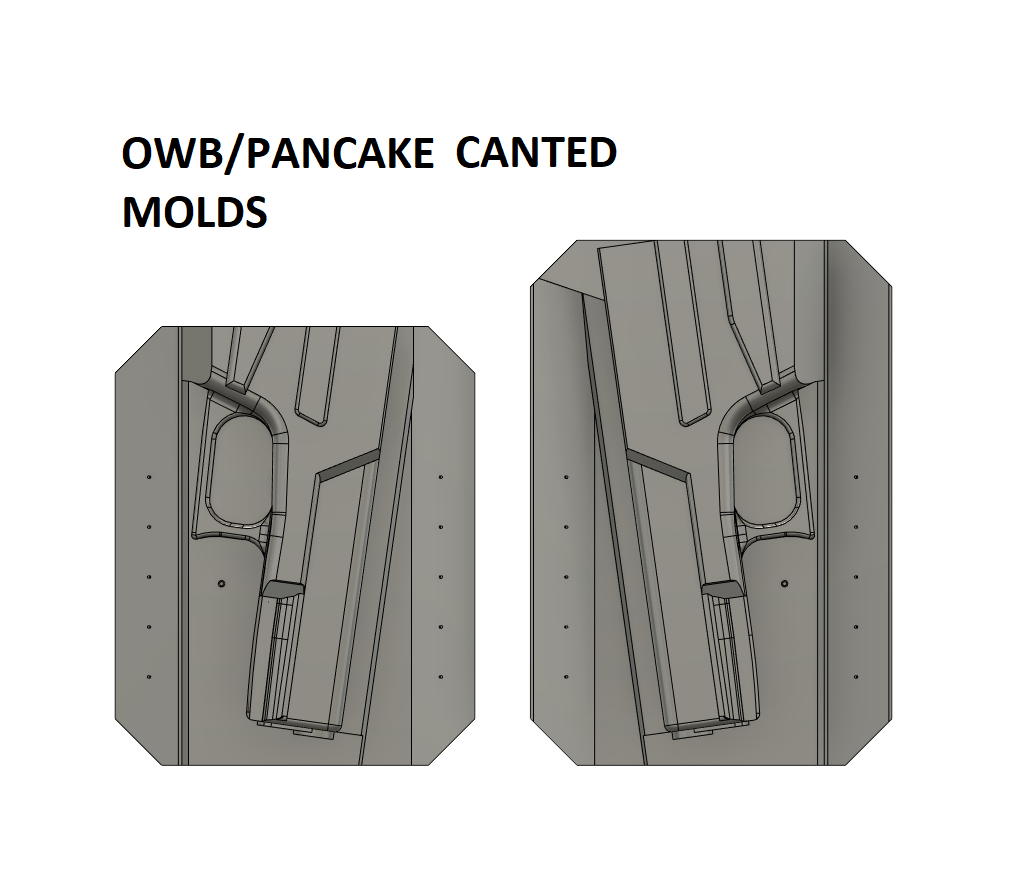

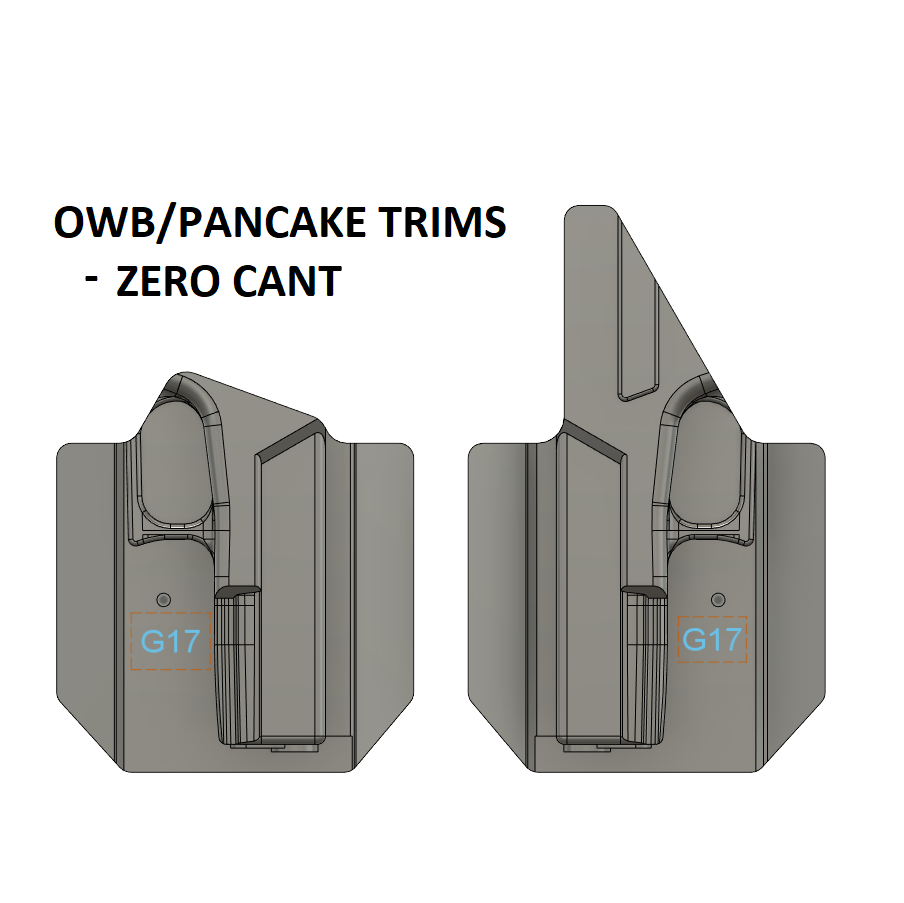

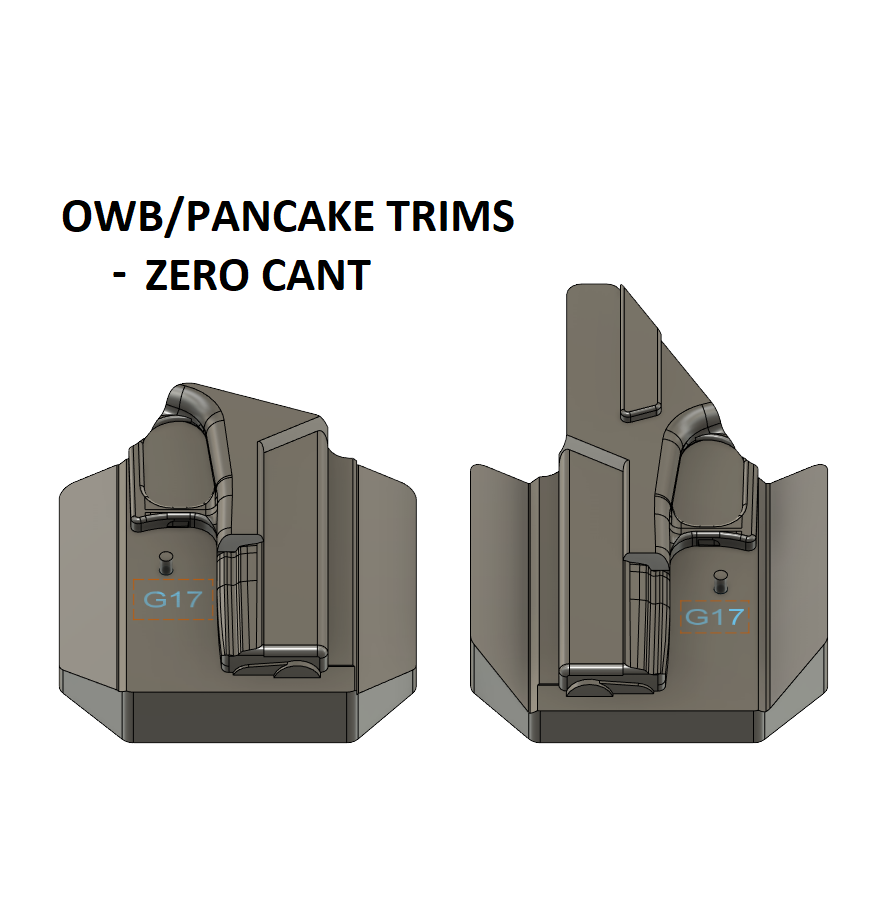

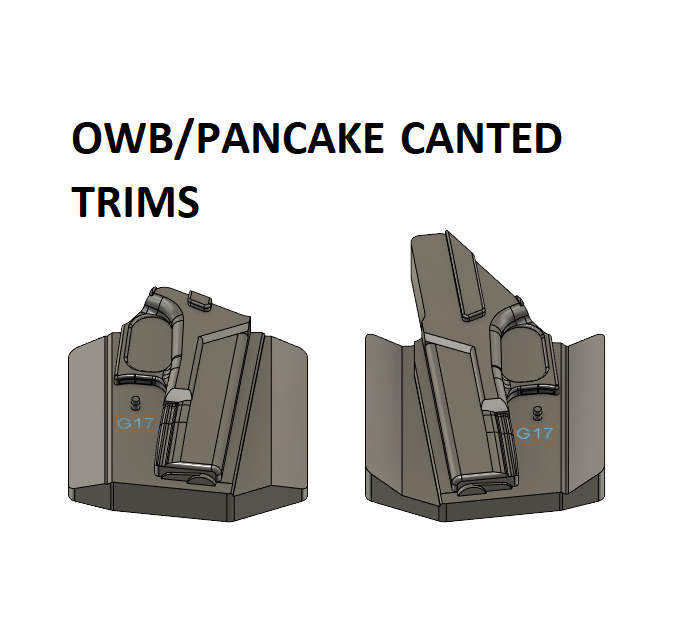

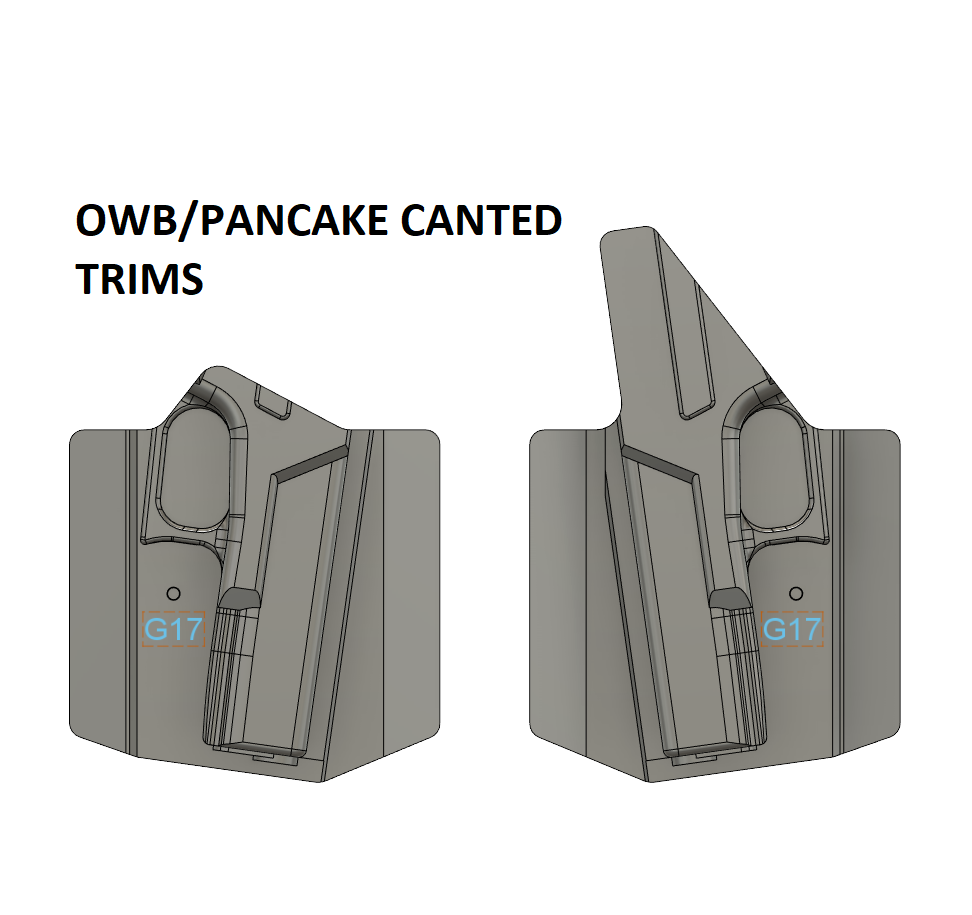

-MOLD STYLES

ZERO CANT/STRAIGHT DROP OWB MOLDS WITH 3/4" SPACED DRILL INDICATORS FOR EYELETS AND BELT LOOPS.

CANTED OWB MOLDS WITH 3/4" SPACED DRILL INDICATORS FOR EYELETS AND BELT LOOPS.

-TRIMMING JIGS

CNC MACHINED FROM HDPE PLASTIC WITH POSTS TO KEEP YOUR SHELL IN PLACE WHILE TRIMMING. THE TRIMMING JIG HELPS YOU AWAY MATERIAL IN STRAIGHT LINES AND WITH REPEATABLE, CONSISTENT HOLSTER SHAPE AND SIZE. THEY CUT AWAY MATERIAL TO ALLOW THE USE OF MOST MRD/ RED DOT OPTICS ON THE MARKET.

MACHINED WITH 0.3" TO 0.5" SIDEWALL HEIGHT FOR USE WITH MOST TRIM BEARING BITS BUT THE TALLER THE CUTTING SURFACE, THE BETTER FOR USE WITH THE OUTER HALF OF THE TRIMMING JIG SET.

Share